Custom robotic hardware design is all about creating specialized components that address the unique needs of a specific robotic system or application. Here are some examples that highlight the versatility and impact of custom hardware in various robotics projects:

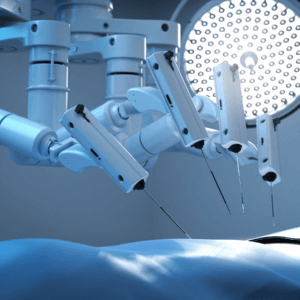

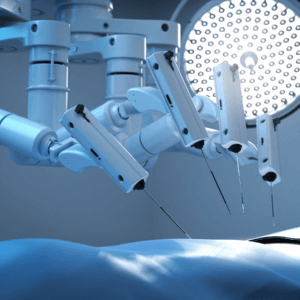

- Custom Actuators for Precision Surgery Robots

Application: Medical Robotics

Challenge: Surgical robots require highly precise movements to perform delicate operations with minimal invasiveness. Off-the-shelf actuators often lack the precision and responsiveness needed for such tasks.

Custom Solution: Custom actuators were designed with high precision and low latency, enabling the robotic arms to make minute adjustments during surgery. These actuators were tailored to fit within the compact structure of the surgical robot while maintaining the necessary force and accuracy.

Outcome: The custom actuators improved the robot’s ability to perform complex procedures with greater precision, reducing the risk of errors and improving patient outcomes.

- Ruggedized Sensors for Autonomous Underwater Vehicles (AUVs)

Application: Marine Exploration and Surveillance

Challenge: AUVs operate in harsh underwater environments where they are exposed to extreme pressures, temperatures, and corrosive saltwater. Standard sensors are not built to withstand these conditions.

Custom Solution: Custom ruggedized sensors were developed to handle the challenging underwater environment. These sensors were encased in corrosion-resistant materials and designed to operate reliably under high pressure and low temperatures.

Outcome: The custom sensors enabled the AUVs to gather accurate data from deep-sea environments, supporting marine research and underwater surveillance missions.

- Compact Power Management Systems for Space Robotics

Application: Space Exploration

Challenge: Space robots, such as rovers and satellites, operate in environments where power is limited and must be carefully managed. Off-the-shelf power management systems are often too bulky or inefficient for space applications.

Custom Solution: A compact and efficient power management system was designed to optimize energy usage and extend the operational life of the space robot. The system included custom PCBs that integrated advanced power-saving features and were designed to withstand the extreme conditions of space.

Outcome: The custom power management system allowed the robot to operate for extended periods on limited power, enabling longer missions and more extensive exploration.

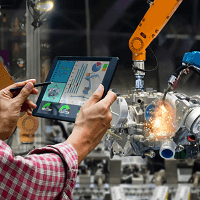

- Specialized End Effectors for Industrial Robots

Application: Manufacturing and Automation

Challenge: Industrial robots often need to handle a wide variety of materials and components with different shapes, sizes, and weights. Standard end effectors are not always versatile enough to meet these diverse needs.

Custom Solution: Custom end effectors were designed to handle specific materials and tasks, such as gripping delicate items without damaging them or manipulating heavy components with precision. These end effectors were also made modular, allowing for easy swapping depending on the task.

Outcome: The custom end effectors increased the versatility of the industrial robots, improving efficiency on the production line and reducing downtime due to tool changes.

- Custom Printed Circuit Boards (PCBs) for Drones

Application: Unmanned Aerial Vehicles (UAVs)

Challenge: Drones require lightweight yet powerful control systems to manage flight dynamics, sensor data, and communication with ground control. Standard PCBs often add unnecessary weight or lack the necessary processing power.

Custom Solution: Custom PCBs were designed to integrate all necessary components into a single, lightweight board. This included advanced processing units, communication modules, and sensor interfaces, all optimized for low power consumption.

Outcome: The custom PCBs reduced the overall weight of the drone, improving flight time and maneuverability, while also enhancing processing power to enable more complex autonomous operations.

These examples illustrate the critical role that custom robotic hardware design plays in advancing the capabilities of robotic systems across various industries. By developing hardware that is specifically tailored to the demands of each application, companies can achieve superior performance, reliability, and efficiency in their robotics projects.

Custom robotic hardware design involves the creation of specialized components that are uniquely tailored to meet the specific needs of a robotic system. Unlike off-the-shelf solutions, custom hardware is designed from the ground up to fit the exact operational requirements, environmental conditions, and performance goals of a robot.

Custom robotic hardware design involves the creation of specialized components that are uniquely tailored to meet the specific needs of a robotic system. Unlike off-the-shelf solutions, custom hardware is designed from the ground up to fit the exact operational requirements, environmental conditions, and performance goals of a robot.

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation