What is AURIS?

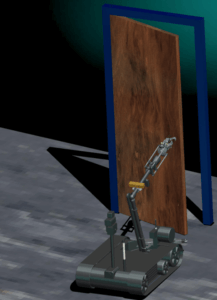

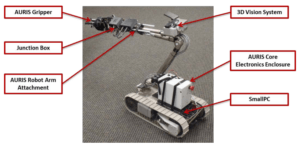

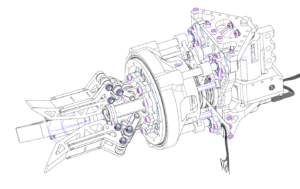

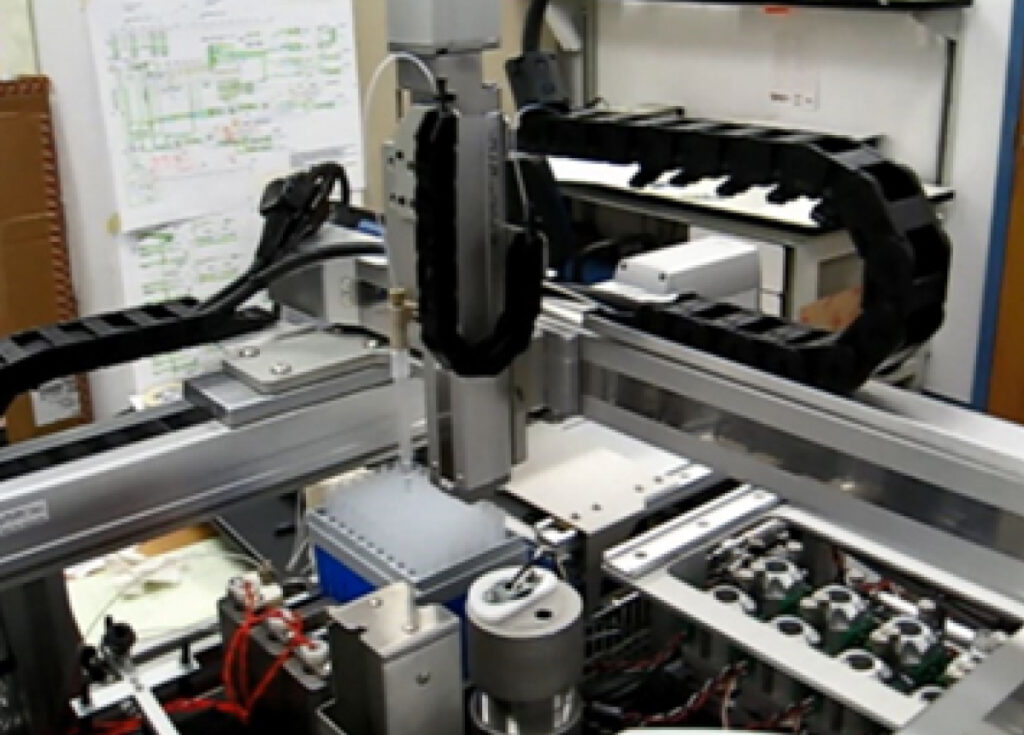

The Autonomous Urban Reconnaissance Ingress System (AURIS) represents a milestone in robotic innovation, solving a critical limitation in modern reconnaissance and tactical operations: the inability of unmanned ground vehicles to open doors. Unlike traditional methods that rely on explosives or manual intervention, AURIS provides a quiet, autonomous, and efficient solution for door ingress, enhancing Unmanned Ground Vehicle (UGV) capabilities in military and first-responder missions. It integrates advanced machine vision, 3D sensing, and robotic manipulation to handle complex door designs and environments seamlessly.

AURIS exemplifies the forward-thinking engineering and establishes a strong foundation for robotics to address real-world challenges. By addressing a fundamental obstacle in urban operations, it contributes to the larger vision of autonomous systems operating safely and effectively in unpredictable scenarios.