Modularity and adaptability have driven innovation in robotics, enabling versatile and scalable solutions. Here are some detailed examples of their application:

- Manufacturing Robots

Purpose: To streamline production processes and accommodate changing assembly requirements.

Details: Modular robotic arms are designed with interchangeable end-effectors, allowing them to switch between welding, material handling, and assembly tasks. These arms also feature quick-connect interfaces for rapid tool changes.

Outcome: These robots increase production line flexibility and reduce reconfiguration time, enabling manufacturers to adapt quickly to shifting market demands.

- Healthcare Robotics

Purpose: To support multiple applications in medical settings, from rehabilitation to surgical assistance.

Details: Adaptive designs allow robots to integrate modular tools, such as diagnostic sensors and therapy attachments. Components are easily swapped to customize the robot for patient-specific needs.

Outcome: The systems improve patient outcomes while reducing equipment costs by consolidating multiple functions into a single platform.

- Autonomous Vehicles

Purpose: To enable multi-purpose functionality in dynamic environments.

Details: Modular platforms support the addition of new sensors, payloads, and mobility configurations. For example, an autonomous vehicle could transition from package delivery to agricultural monitoring by swapping components.

Outcome: These vehicles deliver a significant increase in operational efficiency across various industries.

- Industrial Inspection Robots

Purpose: To inspect a variety of infrastructure types with minimal downtime.

Details: Robots are designed with interchangeable mobility modules (e.g., wheels, tracks, or magnetic crawlers) and sensor arrays. This allows them to adapt to pipelines, storage tanks, or ferrous surfaces seamlessly.

Outcome: These robots reduce inspection costs and improved access to hard-to-reach areas.

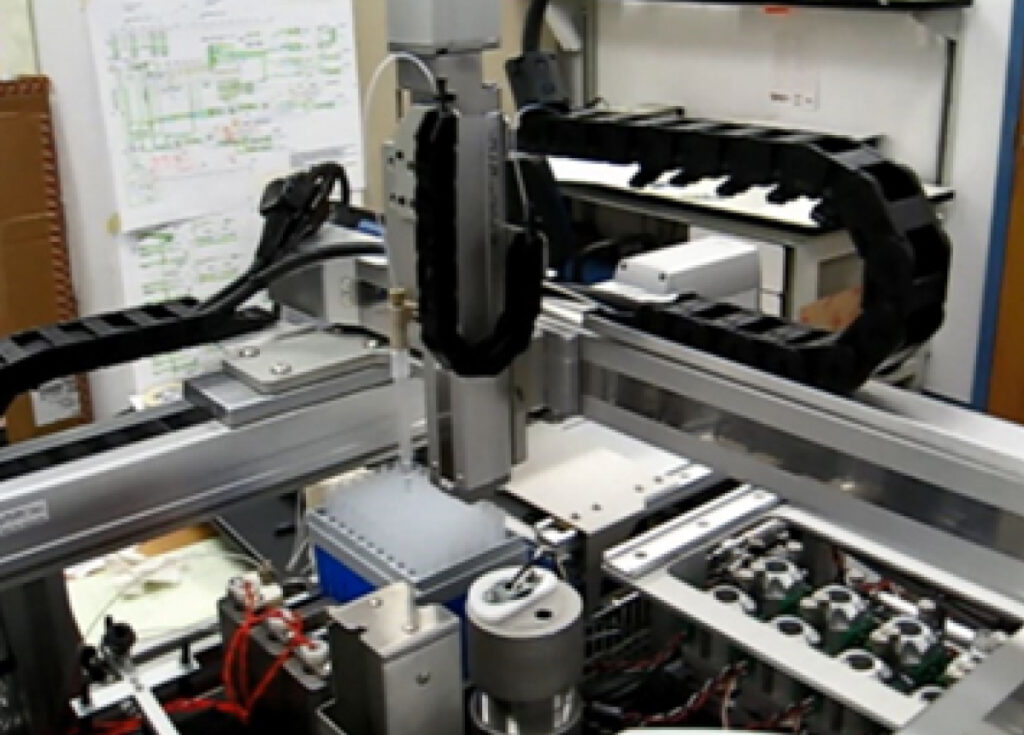

- Research and Development Platforms

Purpose: To provide flexible platforms for testing and prototyping.

Details: Modular robots enable researchers to test various configurations by swapping out actuators, sensors, and control systems. These platforms support rapid iteration without the need for custom-built prototypes.

Outcome: Researchers can accelerate development timelines by 50%, enabling quicker deployment of innovative solutions.

Interdisciplinary Expertise:

Interdisciplinary Expertise:

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation