Environmental adaptation has enabled robots to perform critical tasks across a range of challenging conditions. Here are some detailed examples:

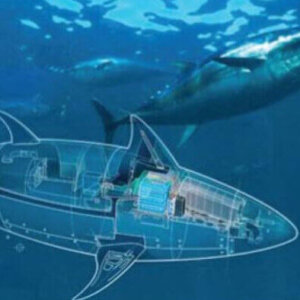

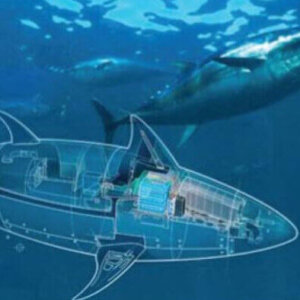

- Underwater Exploration Robots

Purpose: To gather data and inspect underwater structures in deep-sea environments.

Details: Robots are designed with pressure-resistant housings, corrosion-resistant alloys, and advanced navigation systems. Real-time diagnostics monitor internal components to ensure functionality at increasing depths.

Outcome: These robots provide high-resolution imagery and structural assessments, supporting tasks like marine research and offshore infrastructure inspection.

- Industrial Robots for High-Temperature Applications

Purpose: To perform tasks in extreme heat, such as in metal forging and glass manufacturing.

Details: Robots are equipped with heat-resistant materials and cooling systems to protect internal components. Sensors monitor thermal loads to adjust performance in real time.

Outcome: The systems operate reliably in extreme environments, reducing human exposure to dangerous conditions and increasing production efficiency.

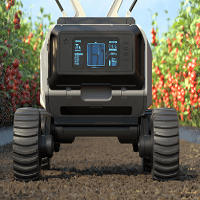

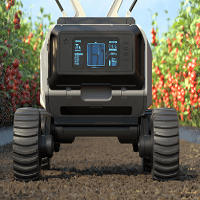

- Autonomous Vehicles for Rugged Terrains

Purpose: To navigate and perform tasks in remote or uneven landscapes.

Details: Vehicles feature ruggedized suspensions, all-terrain wheels, and adaptive navigation algorithms. Environmental sensors detect and adjust for obstacles like rocks, mud, or snow.

Outcome: These vehicles improve logistical operations in agriculture and disaster response, delivering supplies and completing tasks in areas inaccessible to traditional vehicles.

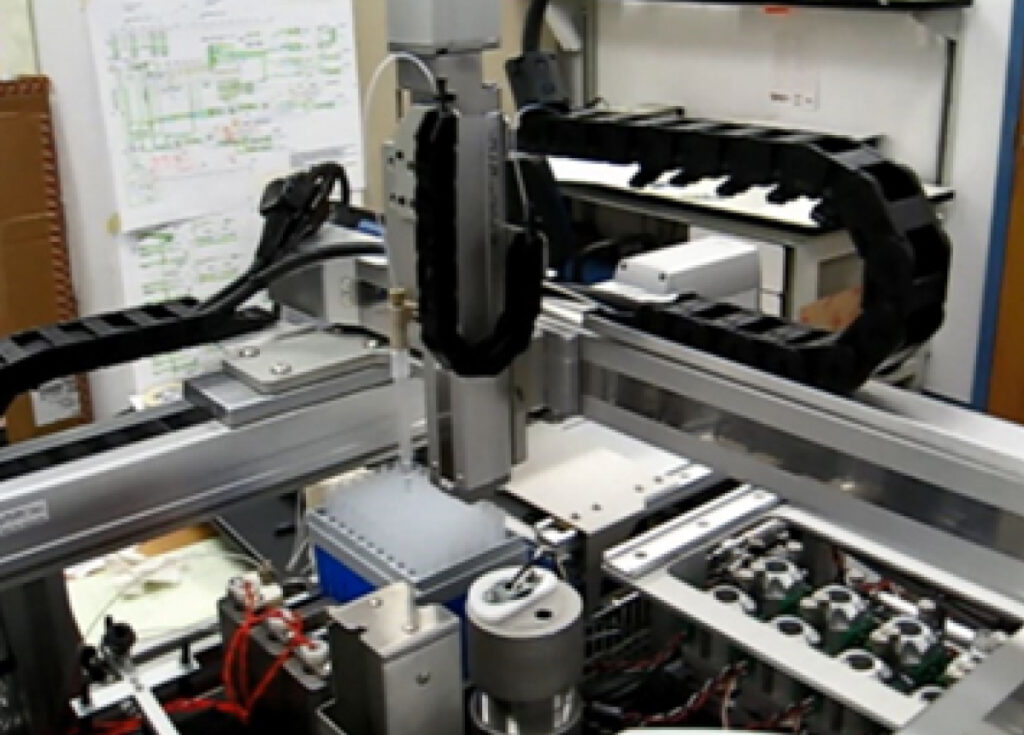

- Cleanroom Manufacturing Robots

Purpose: To maintain precision and cleanliness in controlled environments, such as semiconductor production.

Details: Robots are constructed with non-contaminating materials and sealed enclosures to prevent particle generation. Real-time monitoring ensures adherence to cleanroom standards.

Outcome: These robots enhance productivity while maintaining strict cleanliness levels, supporting industries where contamination can lead to costly errors.

- Robots for Corrosive Environments

Purpose: To handle chemicals and inspect equipment in corrosive industrial settings.

Details: Systems are designed with corrosion-resistant coatings, sealed electronics, and specialized seals to prevent chemical ingress. Regular diagnostics ensures ongoing functionality.

Outcome: These robots operate consistently in environments with high chemical exposure, extending equipment lifespan and minimizing maintenance costs.

Environmental adaptation refers to the ability of robotic systems to perform reliably and efficiently in diverse and challenging environments. This capability involves designing robots that can withstand extreme conditions, such as high pressure, intense heat, corrosive substances, or dynamic terrains. By leveraging advanced materials, innovative designs, and specialized components, robots with environmental adaptation excel in scenarios ranging from deep-sea exploration to cleanroom manufacturing. This ensures that robotic systems maintain optimal performance regardless of their operational setting.

Environmental adaptation refers to the ability of robotic systems to perform reliably and efficiently in diverse and challenging environments. This capability involves designing robots that can withstand extreme conditions, such as high pressure, intense heat, corrosive substances, or dynamic terrains. By leveraging advanced materials, innovative designs, and specialized components, robots with environmental adaptation excel in scenarios ranging from deep-sea exploration to cleanroom manufacturing. This ensures that robotic systems maintain optimal performance regardless of their operational setting.

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation