Precision manipulation has enabled groundbreaking advancements in robotics, revolutionizing industries with its capabilities. Here are some detailed examples:

- Robotic Arms for Micro-Assembly

Purpose: To assemble miniature electronic components with extreme precision.

Details: Multi-DOF robotic arms equipped with high-resolution encoders and force sensors are designed to handle delicate parts without causing damage. Advanced control algorithms ensure precise placement and alignment.

Outcome: These robots can achieve an increase in production efficiency and reduced defects, meeting the stringent demands of the electronics industry.

- Surgical Robotics

Purpose: To enhance precision and control during minimally invasive procedures.

Details: Robots with articulated arms and haptic feedback systems are developed to assist surgeons in performing intricate operations. These systems provide sub-millimeter accuracy and real-time responsiveness.

Outcome: The systems improve patient outcomes by reducing recovery times and minimizing surgical risks.

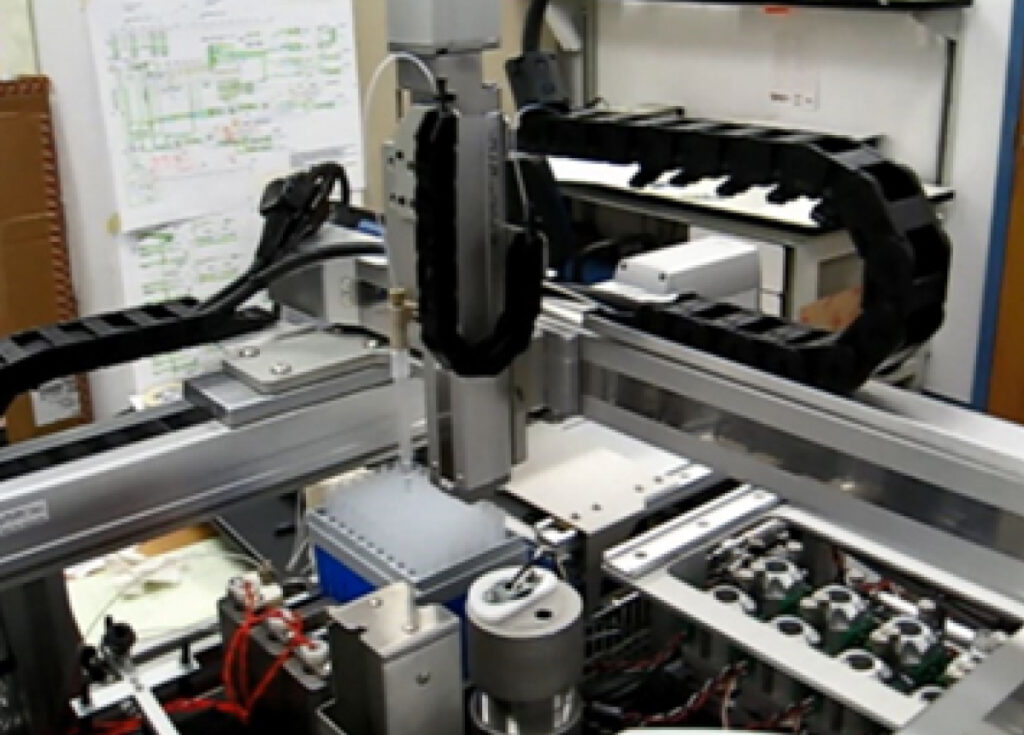

- Laboratory Automation Systems

Purpose: To automate repetitive and delicate tasks in research and diagnostic labs.

Details: Robots with specialized grippers and pipetting tools are programmed for tasks such as liquid handling, sample sorting, and assay preparation. Integrated vision systems ensure accuracy and consistency.

Outcome: These systems increase throughput and improve the reproducibility of experimental results.

- Precision Manufacturing Robots

Purpose: To enhance quality and efficiency in high-stakes manufacturing processes.

Details: Robotic systems with adaptive force control and tactile feedback are implemented to handle fragile materials, such as glass and composites, in production lines. Real-time monitoring optimizes pressure and alignment.

Outcome: These robots reduce material waste and improve product quality across the board.

- Robotic Grippers for Hazardous Materials Handling

Purpose: To safely manipulate hazardous or toxic materials in industrial and research settings.

Details: Robots equipped with customizable grippers and remote-control capabilities are designed to handle dangerous substances with precision. Specialized coatings and seals protect components from contamination.

Outcome: These systems enhance safety and efficiency, reducing the need for human exposure to hazardous environments.

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation