Our Approach to Re-shoring: Challenges and Solutions

At Boston Engineering, we transform the challenges of reshoring into steppingstones for growth and innovation. Here’s how we help:

Value Chain Optimization

Re-shoring manufacturing requires rethinking the entire value chain to maximize efficiency and minimize costs. We help businesses:

- Identify and eliminate inefficiencies in existing product design.

- Transition to domestic suppliers and build secure, localized networks.

- Leverage automation and AI to streamline production and logistics.

A well-optimized value chain enhances operational agility and ensures sustainable long-term growth.

Workforce Transformation

A skilled workforce is the foundation of a successful reshoring initiative. Boston Engineering provides solutions to:

- Implement digital training programs using augmented reality (AR) and virtual reality (VR).

- Develop workforce upskilling strategies to bridge the skills gap.

- Capture and transfer institutional knowledge through AI-driven tools.

By empowering employees with modern technologies, businesses can enhance productivity and efficiency.

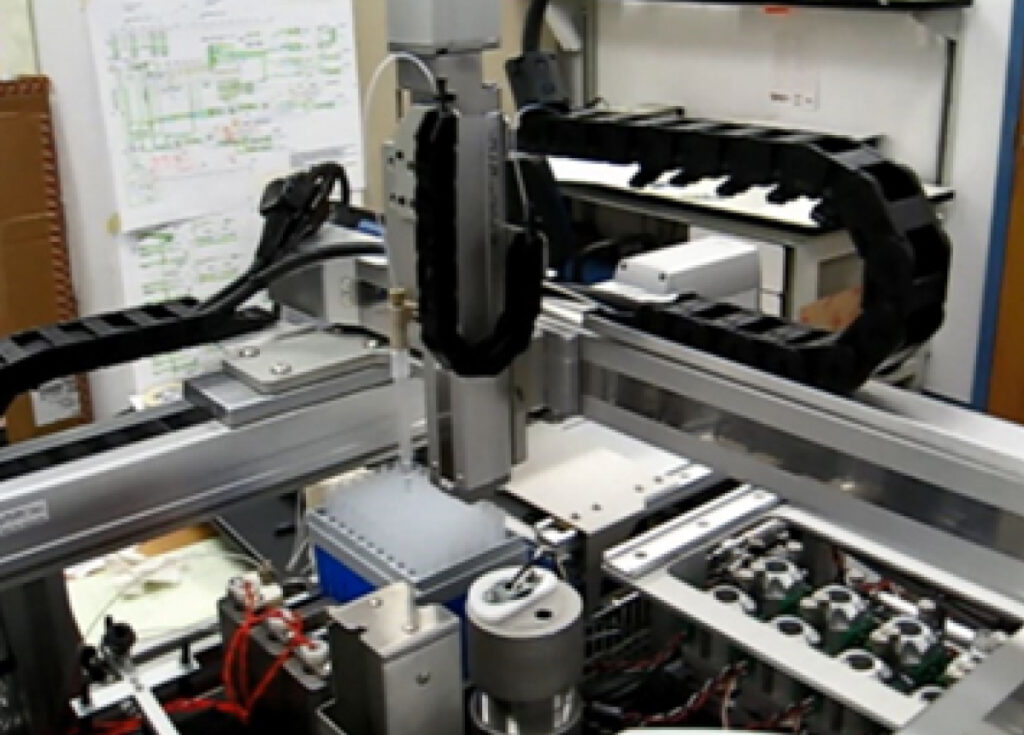

Infrastructure Modernization

A robust and flexible infrastructure is essential for supporting re-shored operations. Our approach includes:

- Integrating advanced manufacturing technologies such as robotics and IoT.

- Utilizing digital twins to simulate and optimize factory layouts.

- Upgrading legacy systems to improve scalability and efficiency.

Modernizing infrastructure ensures that businesses remain competitive and adaptable to future industry changes.

As global supply chains face unprecedented challenges, businesses are turning to re-shoring to build resilience, improve quality, and future-proof operations. At Boston Engineering, we help companies navigate this transformation with advanced technology, strategic planning, and cutting-edge design.

As global supply chains face unprecedented challenges, businesses are turning to re-shoring to build resilience, improve quality, and future-proof operations. At Boston Engineering, we help companies navigate this transformation with advanced technology, strategic planning, and cutting-edge design.