Tailoring Solutions to Meet Unique Challenges

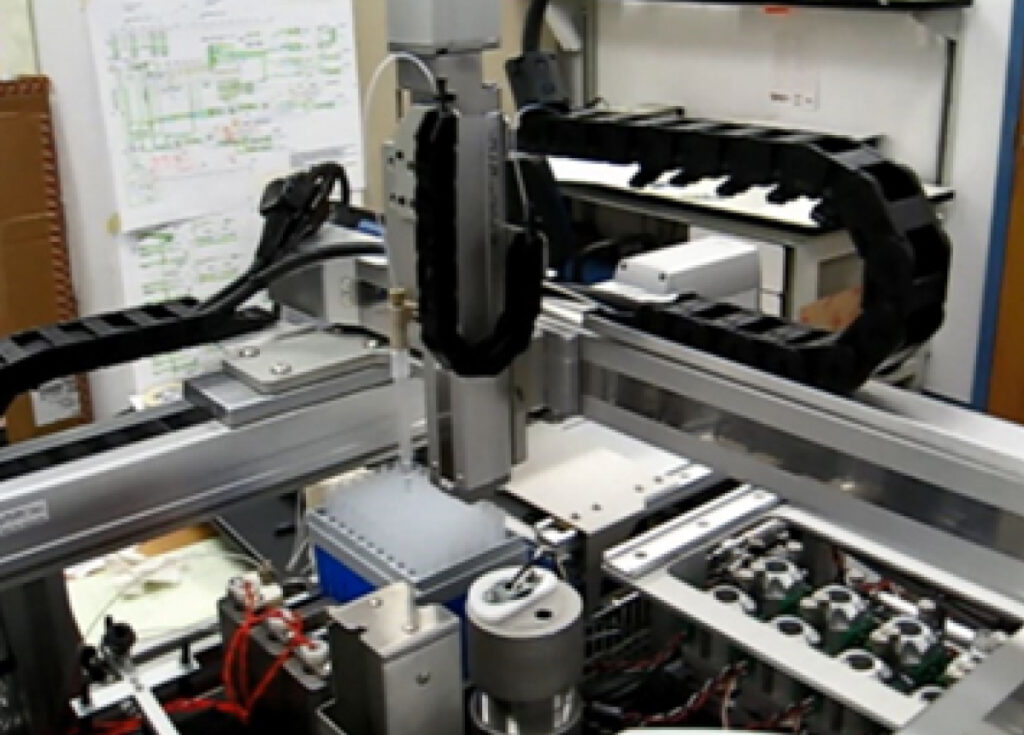

In the rapidly evolving world of robotics, every industry faces unique challenges that require specialized knowledge to overcome. Industry-specific knowledge in robotics ensures that the systems designed are not only cutting-edge but also optimized to meet the unique needs and standards of each sector, from manufacturing and healthcare to agriculture and defense.

At Boston Engineering, leveraging industry-specific expertise is key to providing clients with robotic solutions that are efficient, compliant, and future-proof. By tailoring systems to the particular challenges of each industry, they help businesses gain a competitive edge, improve operational efficiency, and ensure long-term success.

What is Industry-Specific Knowledge in Robotics?

Industry-specific knowledge refers to a deep understanding of the particular challenges, needs, and regulations that define various sectors where robotics are deployed. Each industry has different operational environments, safety protocols, and regulatory requirements, and robotic systems must be designed to address these nuances.

For example, robotic systems in the healthcare industry must meet stringent hygiene and safety standards, while systems in manufacturing must prioritize speed, precision, and reliability to operate in high-demand, fast-paced environments. By understanding these factors, robotics designers can create systems that not only meet the basic functional requirements but also optimize performance within the specific context of each industry.

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation