Our Approach to Product Redesign for Re-Shoring

At Boston Engineering, we transform the challenges of reshoring into steppingstones for growth and innovation. Here’s how we help:

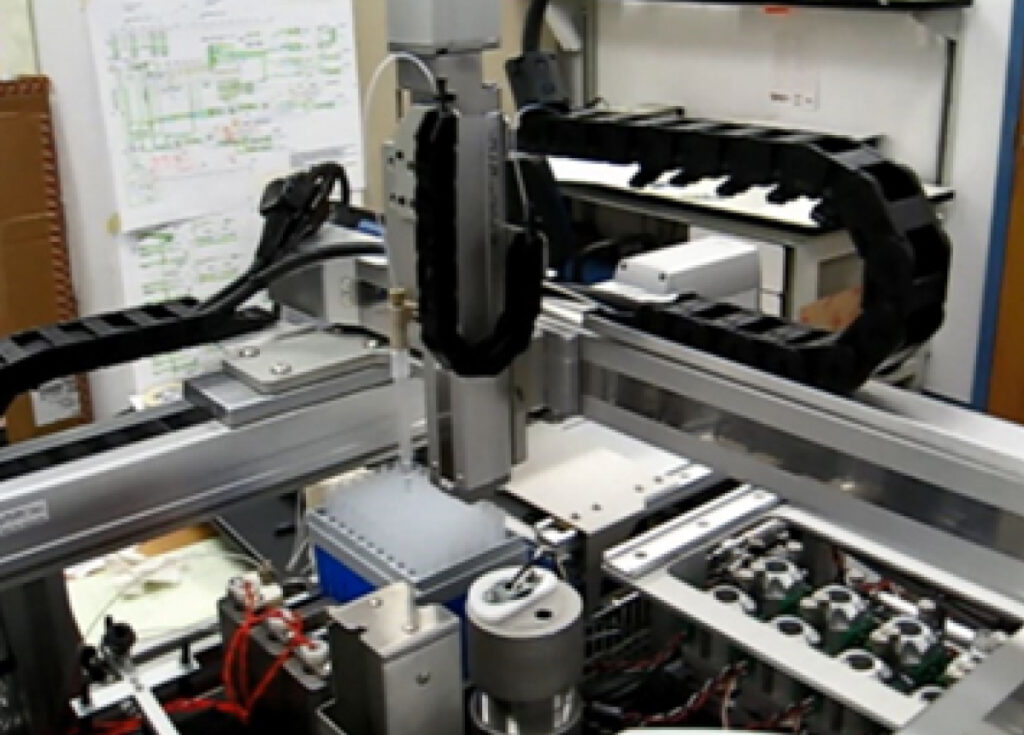

Design for Automated Assembly

Automation plays a crucial role in cost-effective re-shoring. Our design approach includes:

- Optimizing components for robotic and AI-driven assembly.

- Reducing manual processes to enhance efficiency and consistency.

- Implementing modular designs to improve scalability and adaptability.

By integrating automation from the design phase, businesses can achieve higher throughput and lower costs.

Enhancing Design for Cost-Effective Manufacturing

Cost efficiency is a critical factor in reshoring decisions. We focus on:

- Simplifying product designs to minimize material and labor costs.

- Selecting materials that are readily available in domestic supply chains.

- Improving manufacturability to streamline production and reduce waste.

Our cost-focused design strategies ensure competitive pricing without compromising quality.

Leveraging Digital Tools for Product Development

Advanced digital tools enable businesses to refine designs before production, reducing errors and time to market. Our expertise includes:

- Utilizing digital twins to simulate and optimize product performance.

- Implementing 3D printing and rapid prototyping to test design iterations.

- Using AI-driven analytics to predict and resolve manufacturing challenges.

These digital solutions enhance efficiency, reduce development costs, and accelerate time to market.

Transitioning production back to the U.S. often requires reengineering products to align with domestic manufacturing capabilities. Effective product redesign ensures cost-efficiency, quality, and scalability while leveraging advanced manufacturing technologies.

Transitioning production back to the U.S. often requires reengineering products to align with domestic manufacturing capabilities. Effective product redesign ensures cost-efficiency, quality, and scalability while leveraging advanced manufacturing technologies.