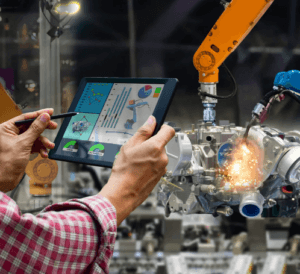

Robotic system integration is the process of connecting various robotic components—such as sensors, actuators, controllers, and software—into a unified, efficient system that performs desired tasks. This goes beyond hardware; it includes integrating software platforms, middleware, communication protocols, and human-machine interfaces (HMIs) to ensure all parts of the robot work harmoniously.

Key elements of robotic system integration include:

Sensor Fusion: Combining data from multiple sensors (e.g., LIDAR, cameras, IMUs) for improved decision-making and system control.

Actuator Control: Seamlessly managing actuators to perform movements with precision and responsiveness.

Middleware Solutions: Using frameworks like ROS (Robot Operating System) to facilitate communication between various hardware and software components.

Human-Machine Interfaces (HMI): Creating interfaces that allow operators to monitor, control, and adjust robotic behavior with ease.

The Importance of Robotic System Integration

Proper integration ensures that a robotic system works efficiently, reliably, and safely. If systems aren’t properly integrated, there’s a risk of communication breakdowns, inefficiencies, and malfunctions, leading to costly downtime or safety issues.

Key Benefits of Robotic System Integration:

- Optimized Efficiency: Integrated systems eliminate bottlenecks, reduce operational errors, and ensure smooth communication between sensors, actuators, and controllers.

- Increased Reliability: Ensuring all parts of the system work together harmoniously improves uptime and reduces the risk of failures or malfunctions.

- Operational Flexibility: Integrated systems are more flexible and easier to modify or expand when new components or features are needed.

- Improved Safety: With better integration, safety systems, such as emergency stops and real-time monitoring, can be more effectively implemented and maintained.

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation