Examples of Safety and Reliability Engineering in Robotics

Automated Guided Vehicles (AGVs) in Warehousing

Safety Challenge: AGVs must navigate busy warehouse environments, avoiding collisions with people, equipment, and other vehicles.

Solution: Safety and reliability engineering includes the integration of sensors and cameras that allow AGVs to detect and avoid obstacles in real-time. Redundant systems ensure that if one sensor fails, others can compensate to maintain safe operation.

Outcome: Reduced accidents and improved efficiency in warehouse operations, leading to lower costs and higher productivity.

Surgical Robots in Healthcare

Reliability Challenge: Surgical robots must perform with extreme precision and reliability, as any malfunction could have severe consequences for patients.

Solution: Reliability engineering ensures that surgical robots have redundant power supplies, fault-tolerant control systems, and are rigorously tested in simulated environments before use in actual surgeries.

Outcome: Enhanced patient safety, reduced recovery times, and higher success rates for complex surgeries.

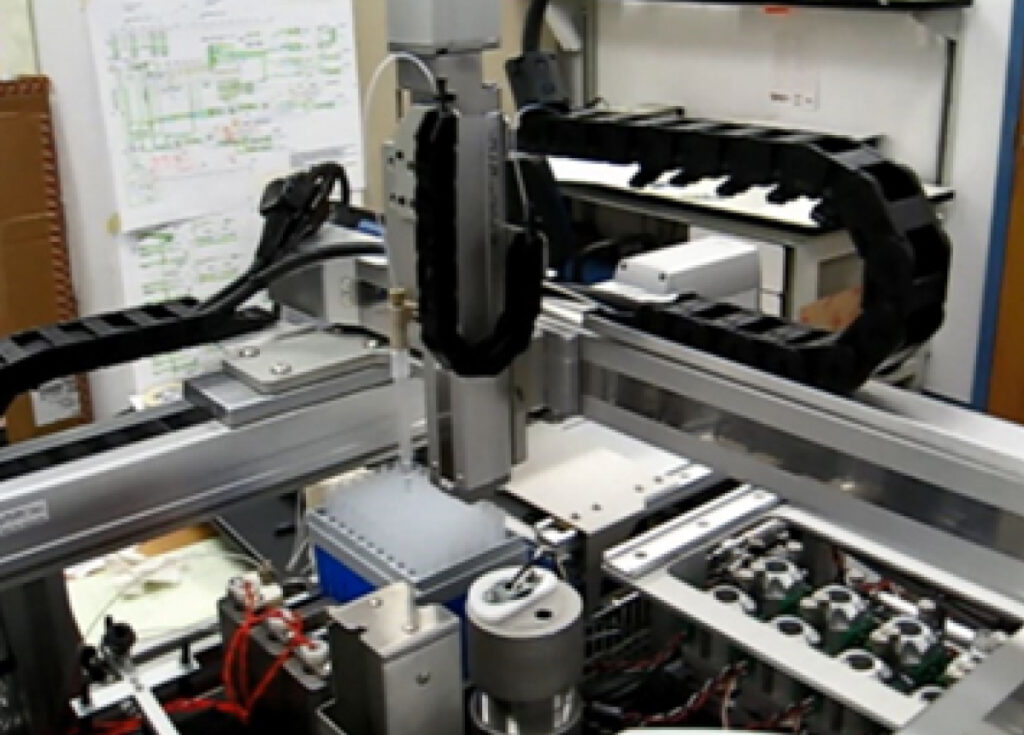

Industrial Robotics for Hazardous Environments

Safety Challenge: Robots operating in hazardous environments, such as nuclear plants or chemical processing facilities, must be able to function safely under extreme conditions.

Solution: Custom robotic designs with robust materials, fail-safes, and remote monitoring capabilities ensure that these robots can operate safely without risking human lives.

Outcome: Improved safety for human workers, as robots take on tasks that are too dangerous for people to perform directly.

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation