Custom and COTS Integration has been a cornerstone of many successful projects, enabling innovative solutions for complex challenges. Here are examples of how this approach is applied:

1. Underwater Robotics

Purpose: To enable reliable operation in deep-sea environments.

Integration Details: Custom pressure-resistant housings are combined with COTS sensors such as sonar and navigation modules. These integrations ensure durability and precise mapping capabilities under extreme pressure conditions.

Outcome: The resulting system provides robust performance for applications like deep-sea exploration, reducing operational risks and delivering high-quality data.

2. Magnetic Crawlers

Purpose: To inspect ferrous surfaces in industrial environments.

Integration Details: Custom magnet arrays are integrated with COTS mobility components, including motors and wheels. This design allows the robot to traverse steel structures such as ship hulls and storage tanks.

Outcome: The crawler navigates hazardous and hard-to-reach areas with efficiency, improving safety and inspection accuracy.

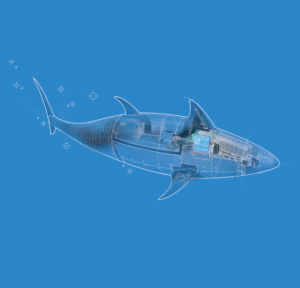

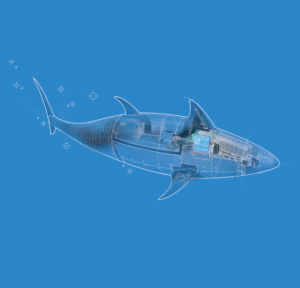

3. Bio-Inspired Vehicles

Purpose: To enhance maneuverability and energy efficiency in underwater applications.

Integration Details: Tailored propulsion mechanisms, inspired by aquatic life, are combined with COTS power units and control boards. This integration optimizes agility and stealth in underwater operations.

Outcome: The vehicle excels in tasks such as environmental monitoring and infrastructure inspection, reducing energy consumption while maintaining precision.

4. Predictive Maintenance Systems

Purpose: To monitor and prevent equipment failures.

Integration Details: Custom diagnostic algorithms are paired with COTS sensors to track the health of components like motors and bearings. These systems predict wear and tear before critical failures occur.

Outcome: Predictive maintenance reduces unexpected downtime and extends the lifespan of robotic systems, offering significant cost savings.

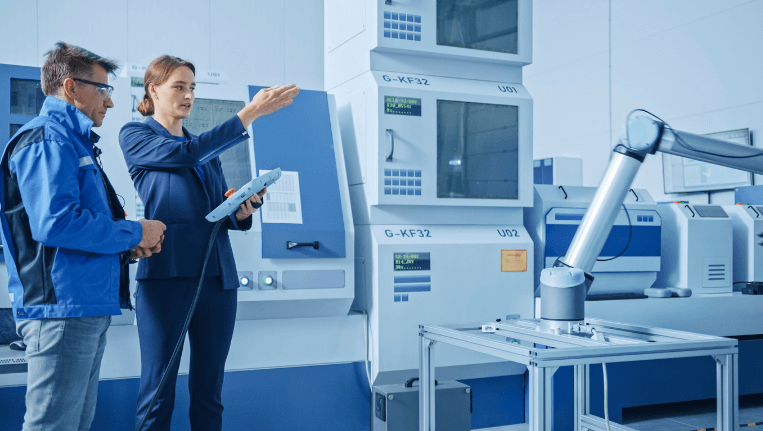

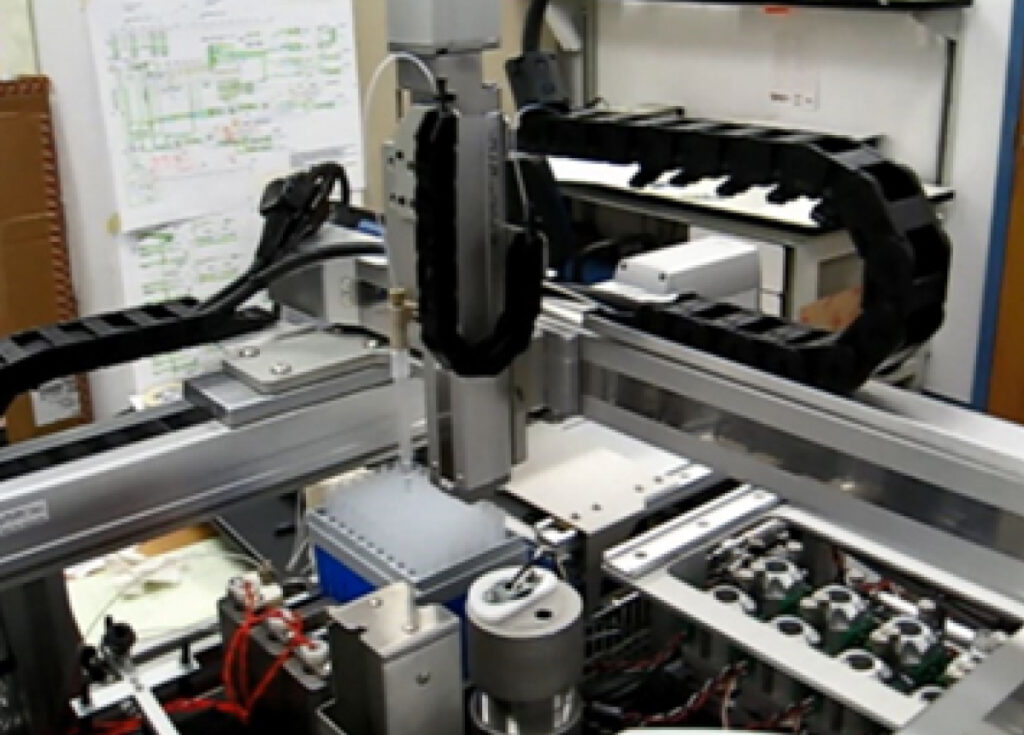

5. Multi-DOF Robotic Arms

Purpose: To perform intricate tasks with precision.

Integration Details: Custom actuators and end-effectors are integrated with COTS motion controllers to enable precise manipulation of small or delicate parts.

Outcome: The robotic arm delivers unmatched accuracy and flexibility in industries like precision manufacturing, meeting exacting standards for quality and efficiency.

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation