Safety and preventive maintenance have played a pivotal role in enhancing the reliability and performance of robotic systems. Here are some detailed examples of their application:

- Collaborative Robotics in Manufacturing

Purpose: To ensure operator safety while maintaining high productivity.

Details: Collaborative robots are equipped with force-limiting actuators, pinch-point prevention mechanisms, and emergency stop systems. Safety sensors monitor proximity to human operators, dynamically adjusting the robot’s speed and force to prevent accidents.

Outcome: The robots significantly reduce workplace injuries while maintaining optimal efficiency, fostering trust in human-robot collaboration.

- Industrial Inspection Robots

Purpose: To minimize risks during critical infrastructure inspections.

Details: Robots used in pipeline and storage tank inspections are integrated with health-monitoring sensors to detect internal component wear and environmental stress. Real-time diagnostics alert operators to potential failures before they occur.

Outcome: These systems reduce unexpected downtime and improve the overall safety of inspection operations.

- Autonomous Vehicles for Logistics

Purpose: To enhance safety and reliability in dynamic warehouse environments.

Details: Autonomous vehicles are equipped with collision avoidance systems and predictive maintenance sensors. The collision systems use LIDAR and ultrasonic sensors to detect obstacles, while onboard diagnostics monitor battery health and motor performance.

Outcome: These vehicles operate seamlessly, reducing accident rates and significantly extending their service life.

- Underwater Robotics for Environmental Monitoring

Purpose: To ensure long-term reliability in extreme underwater conditions.

Details: Pressure sensors and corrosion-resistant components are combined with real-time diagnostics to monitor system integrity. Preventive maintenance algorithms analyze performance data to predict potential failures.

Outcome: These robots provide uninterrupted operation during extended missions, delivering accurate environmental data and reducing maintenance costs.

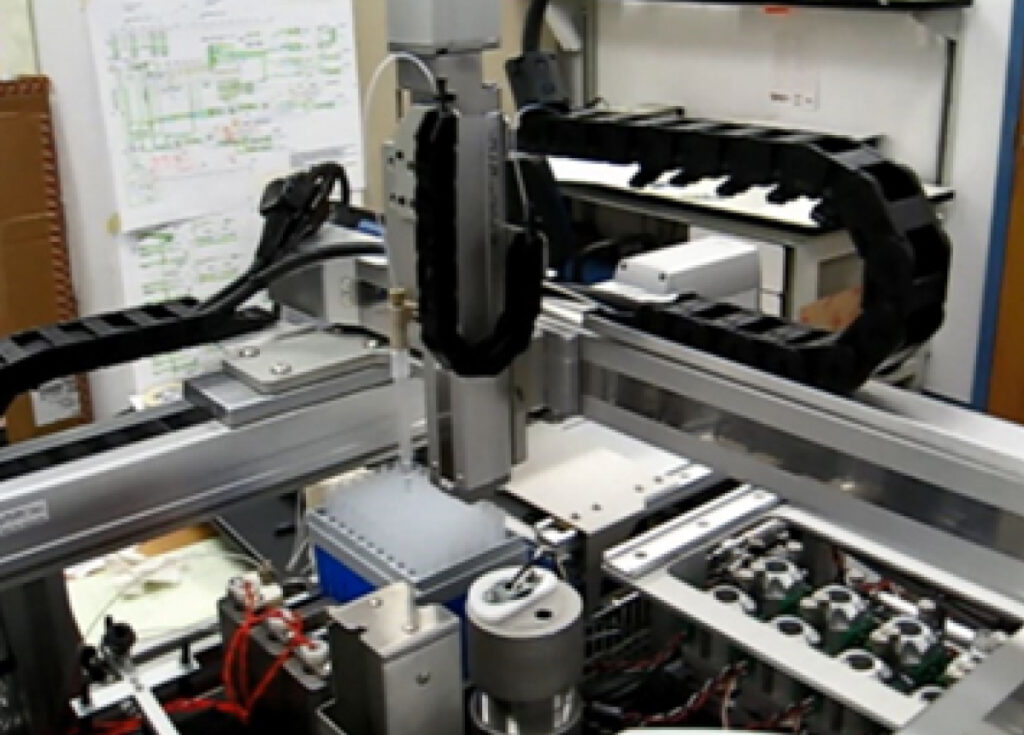

- Precision Manufacturing Systems

Purpose: To maintain consistent output quality and minimize operational disruptions.

Details: Robotic arms in precision assembly lines are equipped with vibration sensors and thermal monitors to track motor performance and detect misalignments. Automated alerts notify technicians of required adjustments or repairs.

Outcome: These systems increase output quality and reduce unplanned maintenance.

Safety and preventive maintenance are essential elements of modern robotic systems, ensuring both the protection of human operators and the long-term reliability of equipment. Safety features, such as emergency stop mechanisms, pinch-point prevention, and soft robotics, mitigate risks during human-robot interactions.

Safety and preventive maintenance are essential elements of modern robotic systems, ensuring both the protection of human operators and the long-term reliability of equipment. Safety features, such as emergency stop mechanisms, pinch-point prevention, and soft robotics, mitigate risks during human-robot interactions.

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation