Specialized materials and manufacturing have transformed the capabilities of robotic systems across industries. Here are a few examples:

- Wearable Robotics for Healthcare

Purpose: To assist in rehabilitation and mobility.

Material Details: Flexible, lightweight composites and bio-compatible polymers create comfortable and ergonomic designs. 3D printing enables rapid prototyping for personalized fits.

Outcome: Wearable robots improve patient outcomes by providing customized support for therapy and mobility assistance.

- Lightweight Drones

Purpose: To extend flight duration and improve agility.

Material Details: Carbon fiber frames and 3D-printed components reduce weight without compromising strength. These materials also improve the drone’s resistance to environmental factors like wind and impact.

Outcome: The drones deliver exceptional performance in applications like aerial surveying, search-and-rescue, and precision agriculture.

- Underwater Exploration Robots

Purpose: To operate reliably in deep-sea environments.

Material Details: Corrosion-resistant alloys and pressure-tolerant composites protect critical components. 3D-printed housings enable precise customization for specific missions.

Outcome: The robots perform consistently in extreme underwater conditions, supporting tasks like infrastructure inspection and marine research.

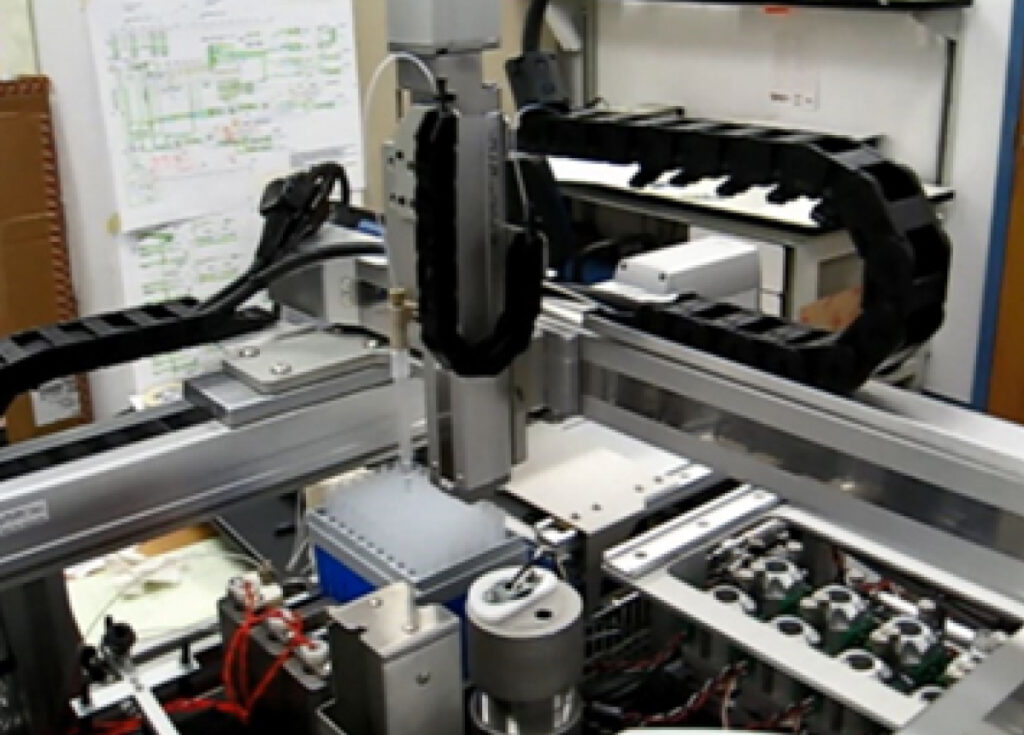

- Industrial Robotic Arms

Purpose: To improve precision and reduce energy consumption.

Material Details: Lightweight aluminum alloys and high-strength polymers reduce inertia and enable faster, more accurate movements. Additive manufacturing allows for optimized end-effector designs.

Outcome: The arms enhance productivity and accuracy in industries like manufacturing and assembly.

- Magnetic Crawlers for Industrial Inspection

Purpose: To navigate and inspect ferrous surfaces in hazardous environments.

Material Details: High-strength magnets and durable composite casings ensure reliable adhesion and protection from harsh conditions.

Outcome: The crawlers effectively inspect storage tanks, pipelines, and ship hulls, minimizing risks and downtime.

Specialized materials and manufacturing involves the use of advanced materials and cutting-edge fabrication techniques to optimize robotic systems. By leveraging materials such as carbon fiber composites, lightweight alloys, and 3D-printed components, engineers can create robots that are stronger, lighter, and more adaptable. This capability ensures that robotic systems perform reliably under diverse and challenging conditions, from industrial environments to underwater applications.

Specialized materials and manufacturing involves the use of advanced materials and cutting-edge fabrication techniques to optimize robotic systems. By leveraging materials such as carbon fiber composites, lightweight alloys, and 3D-printed components, engineers can create robots that are stronger, lighter, and more adaptable. This capability ensures that robotic systems perform reliably under diverse and challenging conditions, from industrial environments to underwater applications.

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation

Our Robotics Experts, along with software and hardware subject matter experts will enhance your current team or drive your entire project. Don’t leave complex projects or high visibility product launches to chance. Know you’re going to get the results you want by working with industry leaders in design, development, and deployment of innovative products driven by novel engineering. Simply complete the form below and let’s start the Robotics Development Project Conversation